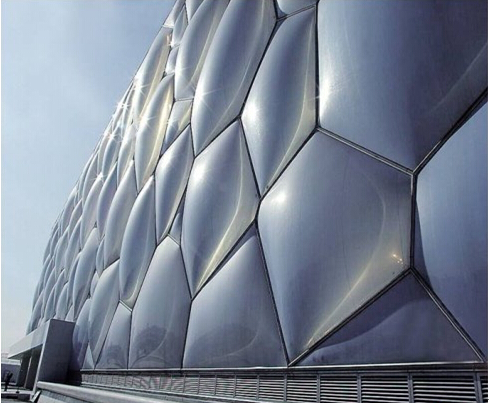

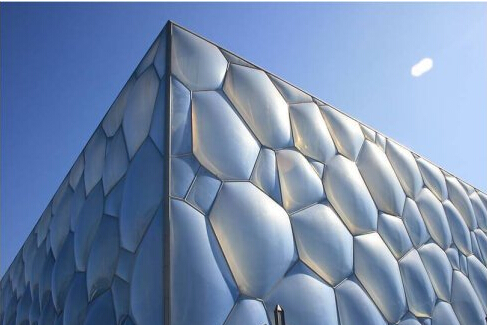

Water Cube Exterior Wall Material-ETFE

Date:2015.5.20 Hit:11204

ETFE is an ethylene-tetrafluoroethylene copolymer. ETFE film is an excellent substitute material for transparent building curtain wall and building roof. It is made of artificial high strength fluoropolymer (ETFE). Its unique anti-adhesion surface makes it highly anti-fouling and easy to clean.

The advantages of ETFE film

1.The material has the corrosion resistance of PTFE, overcomes the non-stickiness and defects of PTFE to metals, and its average linear expansion coefficient is close to that of carbon steel, making ETFE (F-40) an ideal composite material for metals.

2.EFTE film is usually less than 0.2mm in thickness, and its unique anti-adhesion surface makes it highly anti-fouling. In order to clean the main fouling, rainwater can usually clean the main fouling.

3.EFTE is a recyclable material with a life of 25-35 years. It meets the standard of B1 fire prevention grade. The transmittance can be controlled from 50% to 95%.

4.ETFE film has strong self-cleaning property. Because the friction coefficient of ETFE film itself is very small, dust and dirt can not stand on this slippery surface. Even if there is some dust on the surface, as long as it rains a little, the membrane on the facade can be washed very clean.

5.The adjustment of light is attributed to the silver dots on the transparent ETFE film. The lattice formed by these plating points can change the direction of light and has the effect of heat insulation and astigmatism. The required light can pass freely to ensure the temperature and lighting of the venue.

Reasons why ETFE membranes are not popular at present

1. Limited stretching: only about 3M

2. Additional elasticity: The only way to use this material is to apply a "pad".

3. Highly translucent: This is its selling point, but also its shortcomings. Just as television may prefer to use controllable artistic light instead of changing direction of the sun at all times.

4. Mechanical equipment: The liner needs to be supplied with pressurized air. For open-air squares, we may need to monitor about 13,200 pads to prevent leakage.

5. Electricity: Used to ensure air supply, support systems or systems are necessary.

6. Sharp things can damage the material and cause air leakage. Flying debris may also cause substantial damage to the vertical surface.

7. Initial investment: Initial costs are very high, as high as glass panels.

8. Maintenance costs: Daily maintenance is necessary, and a maintenance team needs to be set up.

-

Application of Membrane Structure in Rail Transit...

Application of Membrane Structure in Rail Transit... -

Application of Thermal Insulation Lining Technology in Membrane Archit...

Application of Thermal Insulation Lining Technology in Membrane Archit... -

Application of membrane curtain wall...

Application of membrane curtain wall... -

Application of Membrane Roofing...

Application of Membrane Roofing... -

Application of Membrane Structure in Environmental Protection Engineer...

Application of Membrane Structure in Environmental Protection Engineer... -

Application of Membrane Structure in Sewage Treatment Plant...

Application of Membrane Structure in Sewage Treatment Plant...